BRICS citizens are in for various technological upgrades. According to the BRICS Manufacturing Working Group, which met in Centurion, South Africa, last week, the emerging block explores how to scale up modern solutions to old problems.

The aim is to improve BRICS citizens’ quality of life and enhance sustainability.

The meeting showcased some of the technologies being developed across the BRICS world. These projects aim to improve BRICS citizens’ living standards, reducing manufacturing costs and diminishing manufacturing waste.

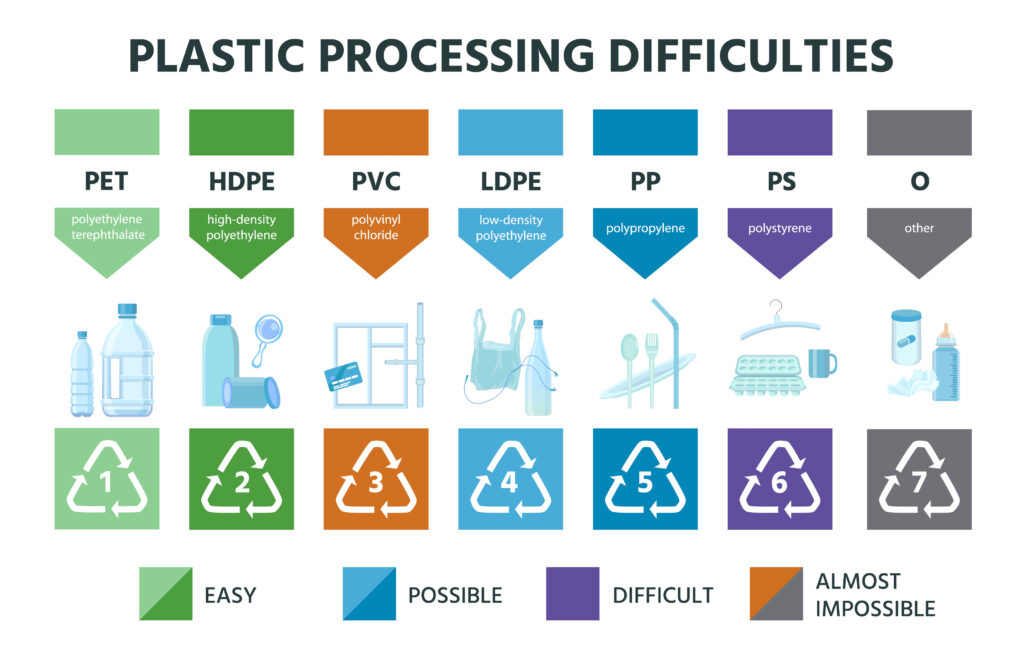

BRICS Bioplastics

Bioplastics offer an essential alternative to conventional plastics, contributing to environmental pollution and depletion of finite fossil fuel resources.

While bioplastics have their advantages, challenges still exist, including the need for efficient recycling systems, proper disposal methods, and addressing concerns about land use for growing feedstock.

Ongoing research and technological advancements will improve bioplastics’ sustainability, cost-effectiveness, and performance.

Here are the main types and categories of bioplastics:

Bio-based plastics

These bioplastics are made from renewable biological materials, such as corn, sugarcane, potatoes, and other plant-based sources. The raw materials undergo processing to extract the necessary components, like sugars or starches, which are then converted into biopolymers.

Biodegradable plastics

Biodegradable plastics can be broken down by natural processes, such as microorganisms, into simpler substances like water, carbon dioxide, and biomass. These plastics typically come from natural sources, such as corn starch or sugarcane, and can be composted under specific conditions.

Bio-based, non-biodegradable plastics

These bioplastics are made from renewable resources but do not naturally break down quickly. They have a reduced carbon footprint compared to traditional plastics and can be recycled.

PHA (Polyhydroxyalkanoates)

PHA is produced by microorganisms like bacteria through fermentation of sugars or lipids. It’s biodegradable and can be used in various applications, including packaging, disposable products, and medical devices.

PLA (Polylactic Acid)

PLA is a bioplastic made from fermented plant starch (usually corn). It’s compostable and can be broken down into natural components. PLA is used in packaging, textiles, food containers, and more.

Bio-based PET (Polyethylene Terephthalate)

Bio-based PET is similar to traditional PET plastic but is made partially or entirely from plant-based sources. It is recyclable and can be used for bottles, packaging, and fibres.

Cellulose-based plastics:

These bioplastics are made from cellulose, a natural polymer found in plants. Cellulose-based plastics are used in items like packaging, films, and coatings.

Also read: Cutting-edge technology sets the stage for BRICS infrastructure boom